Centrifugal pumps serve most of the pumping applications in industries and are the largest in population. However, since the pumps operate by the centrifugal force imparted to the liquid by impeller rotation, the flow capacity varies depending on the discharge pressure and they may not be suitable for certain applications like:

- A small or medium pumping capacity required against high pressure

- To inject or adjust very precise quantity of liquid against varying suction and discharge pressure conditions

- To handle viscous liquids or liquids with high amounts of suspended solids

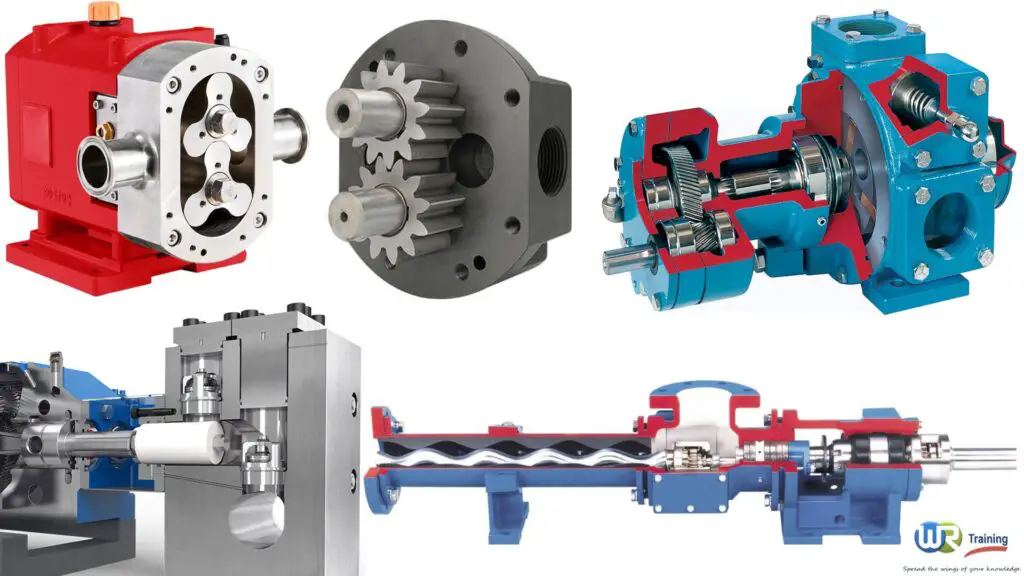

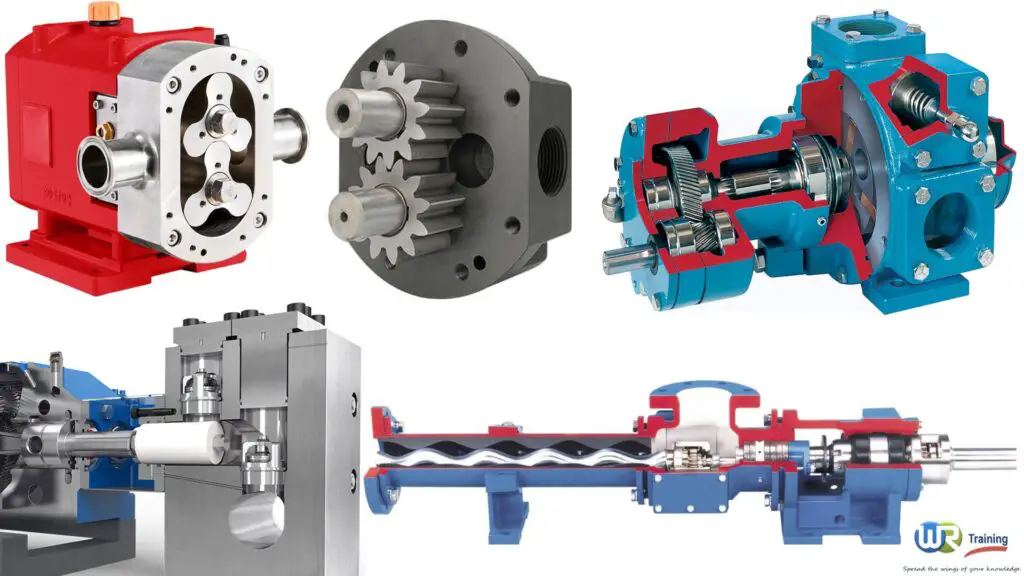

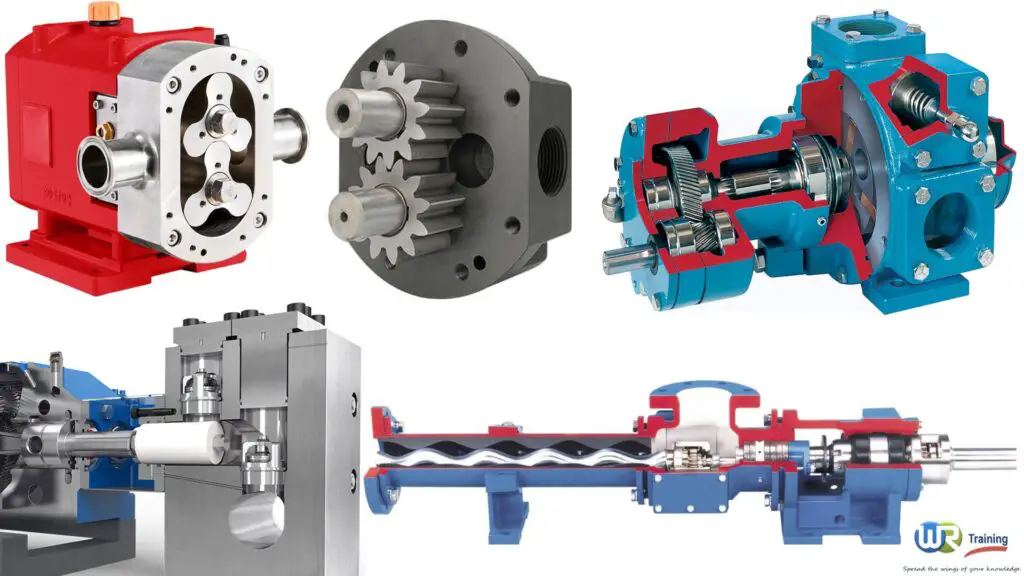

Positive displacement pumps can be used to meet such requirements. This is because they are “constant-flow” machines and operate by forcing a fixed volume of liquid from the inlet pressure section of the pump into the discharge zone of the pump even if the discharge pressure changes.

This course will introduce you to positive displacement pumps, illustrate their main components and their principles of operation.

Both categories of positive displacement pumps (rotary and reciprocating) will be presented and discussed in an easy-to-understand language, using cross-sectional views and 3D animations to give you a virtual practical exposure on this machines.