4 HOURS ON-DEMAND VIDEO

FULL LIFETIME ACCESS

30-DAY MONEY-BACK GUARANTEED

23 DOWNLOADABLE RESOURCES

ACCESS ON MOBILE AND TV

ABOUT THIS TRAINING COURSE

Control in process industries refers to the regulation of all aspects of the process. Precise control of level, temperature, pressure and flow is important in many process applications.

This course introduces you to advanced control in process industries, explains why control is important and identifies different ways in which precise control is ensured for main process equipment such as reactors, pumps, compressors, fired heaters and heat exchangers just to name a few.

The course also introduces you to safety Instrumented Systems (SIS), alarm systems and Interlocks : their anatomy, their requirement, their functions and how they are represented in engineering drawings such as piping & instrumentation diagrams.

- Understand the importance of process control and how it is displayed on your P&IDs

- Successfully interpret basic & advanced process control schemes

- Understand the different process control options and how they are displayed on your P&IDs (cascade control, split range control, ratio control, batch control, selective control…)

- Understand the control of pressure in a pipe and explain how it is displayed on your P&IDs

- Understand the control of flow in a pipe and explain how it is displayed on your P&IDs

- Understand flow merging control and explain how it is displayed on your P&IDs

- Understand flow splitting control and explain how it is displayed on your P&IDs

- Understand centrifugal pump control systems (discharge throttling, variable speed drive, minimum flow…) and explain how they are displayed on your P&IDs

- Understand positive displacement pump control systems (recirculation pipe, variable speed drive, stroke adjustment…) and explain how they are displayed on your P&IDs

- Understand compressor control systems (capacity control, variable speed drive, anti-surge…) and explain how they are displayed on your P&IDs

- Understand heat exchanger control systems (direct control, bypass control, back pressure control…) and explain how they are displayed on your P&IDs

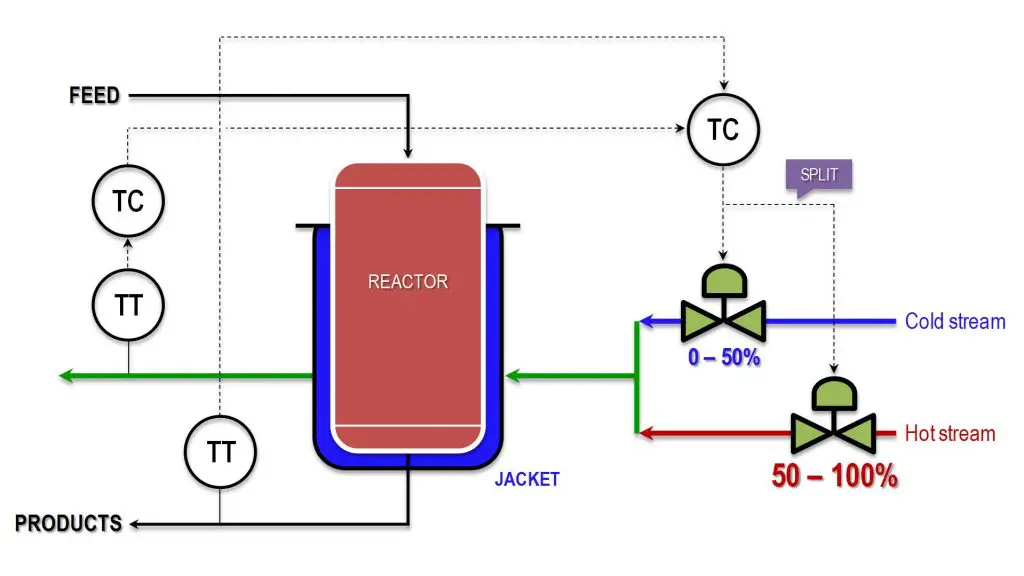

- Understand reactor temperature control systems and explain how they are displayed on your P&IDs

- Understand fired heater control systems and explain how they are displayed on your P&IDs

- Understand container and vessel control systems and explain how they are displayed on your P&IDs

- Understand electric motor control systems (ON / OFF actions) and explain how they are displayed on your P&IDs

- Know and understand the concept of Safety Instrumented Systems (SIS) and explain how safety instrumented functions are displayed on your P&IDs

- Know and understand the concept of Alarm Systems and explain how alarms are displayed on your P&IDs

- Identify safe operating limits based on system designs as displayed on your P&IDs

- Know and understand how Fire and Gas Detection Systems (FGS) are displayed on P&IDs

- Assess emergency situations and regulatory compliance issues using your P&IDs

- All personnel involved in calculation, design, selection, manufacturing, safety, quality and maintenance of systems and equipment in industrial processes

- Plant Operators and engineers in the Process and Power Plant Industries as well as Water and Wastewater Treatment Plants

- Process control engineers & technicians

- Instrumentation engineers & technicians

- Design engineers & technicians

- Piping engineers & technicians

- Maintenance engineers & technicians

- Instructional designers and those involved in writing manuals and operational procedures

- Security, Safety and Environment Officers (SSHE)

- Anyone else with an interest in how P&IDs should be created, maintained and used in assessing emergency situations and regulatory compliance issues

PREVIEW THIS TRAINING COURSE

Would you like to contact us ? We are here to help !

Fore more information about this training course, please fill in the contact form hereafter then click on send :