14 HOURS ON-DEMAND VIDEO

20 DOWNLOADABLE RESOURCES

ACCESS ON MOBILE AND TV

aspen plus ".bkp" + ".txt" files included

FULL LIFETIME ACCESS

30-DAY MONEY-BACK GUARANTEED

ABOUT THIS TRAINING COURSE

Welcome to this online course on chemical engineering simulation using Aspen Plus.

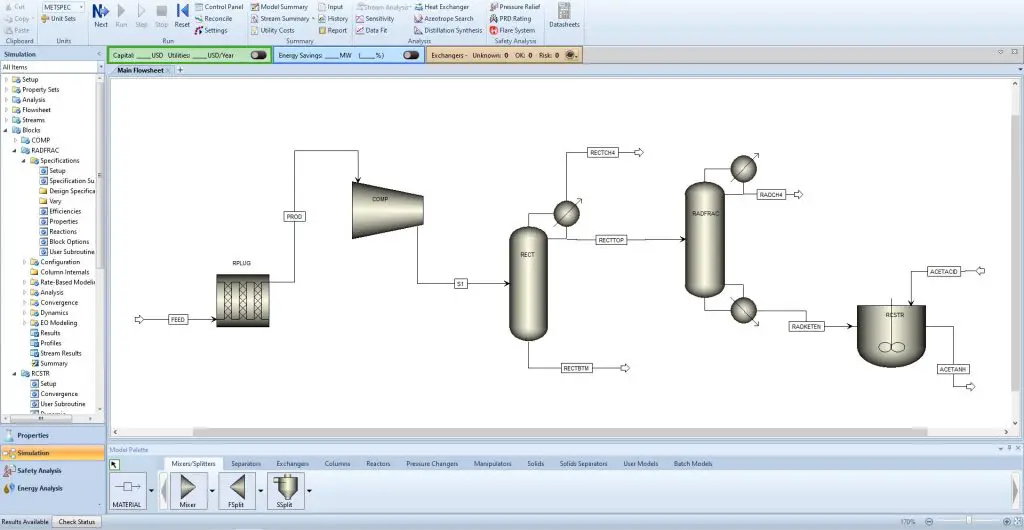

Aspen Plus is a powerful engineering simulation software that you can use to model a wide range of chemical processes.

It is widely used in engineering universities and in the industry, in research, development, modeling and design.

Aspen Plus serves as the engineering platform for modeling processes from Upstream through Gas Processing to Petroleum Refining, Petrochemicals, Chemicals and Pharmaceutical processes.

Online courses about Aspen Plus are difficult to find and when you find them they are either expensive or not professional.

This unique online course is designed around a series of chemical process examples which we work through to a model solution. It is an essential guide to understanding the principles, features and functions of Aspen Plus. This understanding is a prerequisite for a successful design, simulation, rating & optimization of your plant and process equipment.

This unique online course leads you through a process that becomes continuously more difficult, challenging and enriching. When the course content and practice sessions have been completed, we expect that you will have become a competent and advanced user of Aspen Plus.

The course is built with over 9 sections, each tackling a different chemical process and a different aspect of Aspen Plus :

Introducing Aspen Plus

Flash Separation & Distillation Columns

Liquid-Liquid Extraction processes

Heat Exchangers

Piping Systems

Chemical Reactors

Solids Handling processes

Aspen Plus Model Analysis Tools

- Aspen Plus Safety Analysis Environment

The first section explains the basic structure of the software and leads you through a hands-on introduction to the various features of Aspen Plus, designed to facilitate the set up of simple problems.

Features such as the material balance, access to Aspen Plus documentation, the “Next” button, menu navigation, Properties and simulation environments, and the report function are introduced.

The remainder of the course is organized in a series of sections that focus on particular types of operations and processes, for example : chemical reactors, heat exchangers or piping systems.

Each section describes the process being modeled, the way it is modeled, the equations being solved, the various limitations, the potential sources of error, and a set of workshops containing exercises that you should solve to gain experience with the particular subject.

So in just about 14 hours, this unique online course will make you an advanced Aspen Plus user and you will learn how to :

Build, navigate and optimize steady state simulation models using Aspen Plus

Utilize a wide variety of unit operation models and calculation tools to model your process equipment such as distilling columns, reactors, pumps, compressors and piping systems just to name a few

Then Evaluate the performance of your existing equipment by leveraging the equipment rating capabilities of Aspen Plus

Perform Case Studies to determine the optimum operating points for your process

Use the Model Analysis Tools to run sensitivity analysis and optimize your process

And finally Use Aspen Plus in thermodynamics instruction for property analysis of pure components and mixtures

The knowledge gained in this course will set you apart from your peers, whether you are a graduate student, a practicing chemical engineer, or a manager, and will give you an edge over your competitors when seeking employment at industrial facilities.

So with no further ado, check out the free preview videos and the curriculum of the course and we look forward to seeing you in the first section.

Also remember, as enrolled student you will have unlimited access to this material and one-on-one instructor support. So feel free to ask us for help in the Q&A section when needed. It will be our pleasure to help you and make sure you are learning valuable information with us.

Hope to see you there

- Identify the benefits of process simulation using Aspen Plus

- Describe the capabilities of Aspen Plus

- Familiarize yourself with Aspen Plus graphical user interface and organizational structure

- Learn the basic concepts necessary for creating simulations in Aspen Plus

- Enter necessary elements to fully define a fluid package

- Select the appropriate property method for your application

- Define material streams and connect unit operations to build a flowsheet

- Modify and set desired units of measure

- Review stream analysis options

- Add and connect unit operations to build a flowsheet

- Use the Report Manager to create custom unit operation and stream reports

- Use Aspen Plus to perform property analysis of pure components and mixtures

- Use Aspen Plus in thermodynamics instruction for Vapor-Liquid, Liquid-Liquid and Vapor-Liquid-Liquid Equilibrium calculations

- Build, navigate and optimize steady state simulation models using Aspen Plus

- Utilize a wide variety of unit operation models and calculation tools to model process equipment

- Evaluate the performance of existing equipment by leveraging the equipment rating capabilities of Aspen Plus

- Perform Case Studies to determine the optimum operating points for a process

- Design, revamp and debottleneck process equipment

- Use the Model Analysis Tools to run sensitivity analysis and optimize your process

- Calculate process performance and thermophysical data with user subroutines in Fortran

- Investigate reasons why a simulation may produce poor results or errors

- Use suggested tips to debug a variety of simulations

- Understand best practices and learn how to troubleshoot simulations

- Identify and explain the various classes of distillation and separations models available in Aspen Plus

- Gain the skills and knowledge to model distillation, separation and extraction processes

- Reduce process design time by using advanced features of RadFrac distillation columns

- Use column analysis tools to optimize the feed location and number of stages and improve energy utilization for distillation columns

- Add and manipulate column specifications to meet process objectives

- Construct, run, manipulate and analyze a distillation column

- Specify required parameters in order to execute flash calculations and fully define material streams

- Identify and explain the various classes of reactor models available in Aspen Plus (PFR, CSTR…)

- Model Plug Flow, Continuous Stirred Tank and Fluidized Bed Reactors

- Enter reaction stoichiometry and kinetic dats for simple (POWERLAW) and complex (LHHW) reaction types

- Use the Model Analysis Tools to run sensitivity analysis and optimize the operating conditions of a chemical reactor

- Use the Model Analysis Tools to run sensitivity analysis and optimize the selectivity of a given chemical reaction

- Identify and explain the various classes of piping system models available in Aspen Plus (pipes, valves, pumps, compressors)

- Model piping components (pipes, fittings, valves…)

- Model fluid movers (pumps, compressors)

- Model piping systems

- Mitigate the risk for cavitation or choked flow using Aspen Plus

- Learn how to economically optimize your piping system

- Compare and contrast the applicability and operation of different heat exchanger models available in Aspen Plus

- Learn the fundamentals of producing an optimized shell & tube heat exchanger design

- Implement Aspen Exchanger Design & Rating (EDR) for rigorous heat exchanger calculations within Aspen Plus

- Use the Activated Exchanger Analysis feature for continuous heat exchanger study and design

- Design and rate a shell and tube heat exchanger using the EDR interface inside Aspen Plus

- Identify and explain the various classes of solids and solids separator models available in Aspen Plus

- Gain the practical skills and knowledge to begin modeling new and existing solids processes (crushers, fluidized beds, dryers, crystallizers…)

- Familiarize yourself with Aspen Plus Safety Analysis Environment

- Size and rate Pressure Safety Valves PSVs

- Learn practical techniques for building and troubleshooting solids models

- Get the necessary exposure to steady-state simulation as preparation for using Aspen Plus Dynamics®

- Engineers who will be using Aspen Plus in their daily work

- Process engineers doing process design and optimization projects and studies

- Plant engineers checking plant performance under different operating conditions

- R&D engineers and researchers using Aspen Plus for process synthesis

- Engineers wishing to gain experience in simulating distillation and separation processes

- Engineers wishing to gain experience in simulating chemical reactors

- Aspen Plus users who want to improve their skills at analyzing reactions and designing reactors

- Engineers wishing to gain experience in heat transfer and heat exchanger design

- Thermal and process heat exchanger design professionals wishing to enhance their understanding of thermal design and simulation

- Process Engineers and Particle Scientists who will be modeling solids processes

- Engineers and Managers involved in developing and designing solids handling processes

- Safety and process engineers involved in sizing and rating Pressure Relief Devices such as Pressure Safety Valves or Rupture Disks

- Aspen Plus users who need exposure to steady-state simulation as preparation for using Aspen Plus Dynamics®

- A background in chemical engineering or industrial chemistry

- Aspen Plus (Version 7 at least) – Version 11 is used in this training

This course is built with over 9 sections, each tackling a different chemical process and a different aspect of Aspen Plus. Feel free to jump to the sections that most interest you especially if you’re a little bit more advanced. If you’re starting from scratch or even if you’re not, we do highly recommend starting from the beginning.

Aspen Plus is a complex process simulator and, in our opinion, the best way to learn is with hands-on experience, by attempting each example provided in this online course, and when difficulties are encountered, by referring to the problem setup and solution that you can find in the downloadable resource section.

The downloadable resources contain the input and solutions to all of the examples and workshops covered in this online course. There is a root folder for each section, within which, there are subfolders named Examples. Each example is provided in .bkp Aspen Plus format and .txt format. The .bkp files are set up as input files to view details and may be executed. The .txt files are solutions and may be viewed with Notepad. We recommend that while reading the text, Aspen Plus be used simultaneously to execute and review each example.

Lastly, we have made an effort to provide the describing equations of most of the models referred to in this online course and if not possible, because of the proprietary nature of the software, we have described the functionality. Please keep in mind that Aspen Plus is a proprietary software and the source code and implementation details are not available. Additionally, there are frequently several ways to solve the equations that describe the blocks, and there is no way to ascertain these details since Aspen Technology does not provide them.

The Aspen Plus software, like most other software, is being developed on a continuous basis and new versions are released frequently.

This online course covers Aspen Plus version 11, which is the most recent version at the moment we recorded this video.

Please keep in mind that this online course covers the fundamental features of Aspen Plus which do not change from version to version.

The course covers the use of Aspen Plus on computers that use the Windows operating system.

We assume that Aspen Plus is installed on your computer and that you have basic knowledge of operating the computer.

If you are new to Aspen Plus and have little or no experience in chemical engineering simulation, then you have come to the right place.

PREVIEW THIS TRAINING COURSE

Would you like to contact us or to book an Aspen Plus Live Virtual Training or In-House training in your premises ? We are here to help !

Fore more information, please fill in the contact form hereafter then click on send :