3.5 HOURS ON-DEMAND VIDEO

9 DOWNLOADABLE RESOURCES

ACCESS ON MOBILE AND TV

FULL LIFETIME ACCESS

30-DAY MONEY-BACK GUARANTEED

ABOUT THIS TRAINING COURSE

Distillation columns of various designs and applications are encountered nowadays throughout petroleum refining, petrochemical, chemical and process industries.

This course is designed to provide you with a complete understanding of construction details and functioning of distilling columns. This understanding is a prerequisite for successful operation of your plant.

The course features 5 major items :

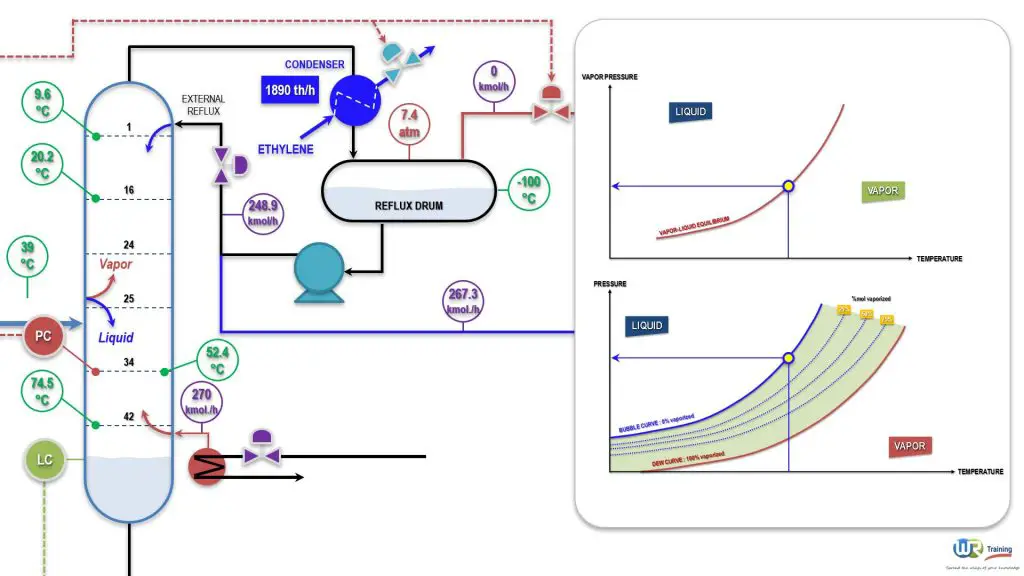

1- VAPOR LIQUID EQUILIBRIA : (thermodynamics of pure components and complex mixtures)

Volatility of pure components : boiling point, vapor pressure

Concept of Sensible and Latent Heat

Behavior of mixtures in distillation : dew and bubble points, vaporization curves, total/partial condensation and vaporization, liquid-vapor separation and distribution of components according to their volatility

Relation between temperature, pressure and composition of distillate and residue

…

2- INDUSTRIAL DISTILLATION PRACTICES :

Operating parameters of an industrial distillation column (Pressure, Temperature, Flow rates, Reflux Ratio…)

Separating power : number of stages, liquid and vapor traffics, feed inlet location

Column pressure : pressure control and pressure profile along the column

Internal flow rates profiles, concentration and temperature profiles, concentration peaks

Material balance of the column : concepts of cut point, separation quality and fractionation capability

Heat balance : condenser and reboiler duties, Reflux and Boil-up ratios and industrial configurations

Instrumentation and process control loops around the column

…

3- INDUSTRIAL DISTILLATION EQUIPMENT :

Trays : technology, performances, flexibility

Packings (structured or random) : technology, performances, flexibility

Different types of contacting systems for the active area : bubble caps, fixed or floating valves

Liquid or vapor distributors, collectors and redistributors

Troubles such as flooding, weeping, fouling…

…

4- ASSESSING DISTILLING COLUMN PERFORMANCE USING ASPEN PLUS (A CHEMICAL ENGINEERING SIMULATOR)

Base case

Effect of temperature

Effect of pressure

Effect of feed stage location

Effect of reflux ratio

…

5- SOLVED PROBLEMS

Ethylene / Ethane fractionator

Reboiler operation

Flash separator

Distilling column overhead operations

Depropanizer case study

…

Many images, cross sectional views, graphs and animations can be found throughout, increasing the value of this course as an educational tool and industrial reference for personnel involved in distilling operations.

So this course is not only of use to practicing engineers and operators to whom a knowledge of the distillation process is of crucial importance in efficient operation of distilling columns but also intended as a study guide for undergraduates in process, chemical, petrochemical & petroleum engineering disciplines.

So with no further ado, check out the free preview videos and the curriculum of the course and we look forward to seeing you in the first section.

Hope to see you there

- Understand the thermodynamics of Vapor Liquid Equilibria for pure components and mixtures

- Know, understand and master the concepts necessary to optimize the operation of your distillation column

- Know about all parameters and profiles for the analysis of your distillation column operation

- Detect deficiencies in the operation of your distilling column, find their origin and solutions

- Know and understand the operating variables and process control systems used for your distillation column

- Know the different types of internals, how they operate and how you can optimize them

- Use the Aspen Plus simulation results to understand and predict the performance of a distillation column

- Chemical engineers

- Process engineers

- Design engineers

- Process control personnel and technical staff in the refining, petrochemicals, chemical and process industries

- Production and Shift Supervisors in charge of distilling columns

- Field Operators

- Experienced field operators preparing for console operations

Some engineering or field knowledge is preferable but not mandatory. All the concepts are explained in depth using an easy to understand language to allow students to build their knowledge from the ground up

PREVIEW THIS TRAINING COURSE

Would you like to contact us or to book a Live Virtual Training or In-House training in your premises ? We are here to help !

Fore more information, please fill in the contact form hereafter then click on send :