3 HOURS ON-DEMAND VIDEO

ACCESS ON MOBILE AND TV

FULL LIFETIME ACCESS

30-DAY MONEY-BACK GUARANTEED

ABOUT THIS TRAINING COURSE

Welcome to this online course on process control & instrumentation.

Control in process industries refers to the regulation of all aspects of the process. Precise control of level, temperature, pressure and flow is important in many process applications.

This online course introduces you to control in process industries, explains why control is important, identifies different ways in which precise control is ensured and illustrates the different set of instrumentation used to perform measuring tasks for temperature, pressure, flow and level.

The course includes extensive graphics, cut sections, process schemes and 3D animations to give you a virtual practical exposure on process control and instrumentation.

The objective of this course is twofold :

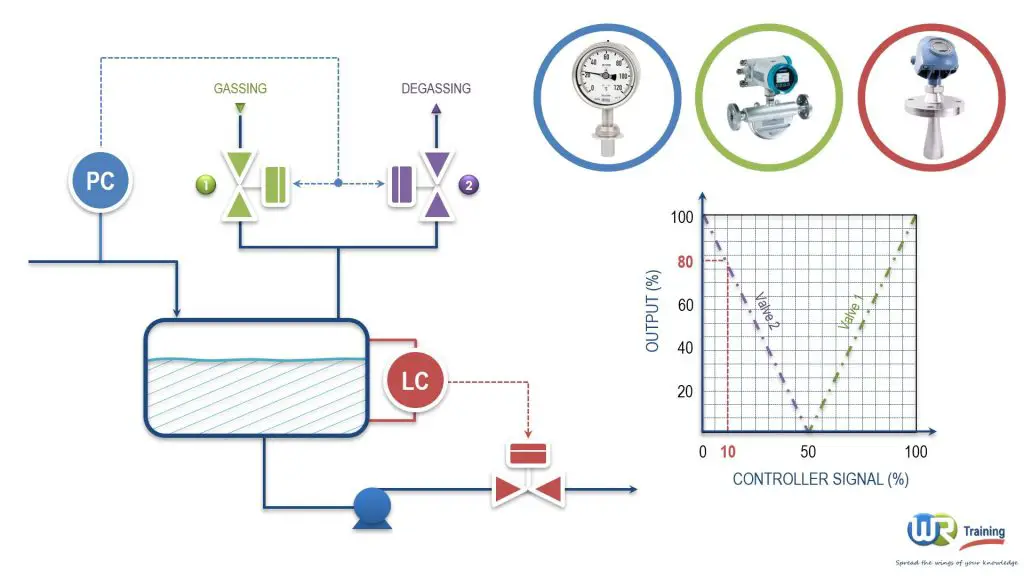

1. Break down for you all the process control and instrumentation principles into easily digestible concepts like feedback control, split range, controller tuning, transmitters, differential pressure gauges, etc…

2. Illustrate through 3D animations and cut-sections the main control instrument devices to measure temperature, pressure, flow and level like thermocouples, capacitive pressure gauges, coriolis flowmeters, etc…

As you proceed through the course, answer the questions in the attached pdf quiz files. These files are available at the end of each section.

We strongly advise you to do so before moving on in the course. Quiz exercises help you measure your progress toward meeting each section’s learning objectives.

If you pass, wonderful. If not, you can review the videos and notes again or ask us for help in the Q&A section.

-

- Learn the essentials of process control and instrumentation for a successful career in process industries

- Understand the main terms and parameters of process control (Process variable PV, Set point SP, Operating point OP, Error, Offset, Load disturbance…)

- Identify the different control loops and describe their main tasks

- Describe the basic function and method of operation for the main control loop components (Transducer, Converter, Transmitter, Indicator, Recorder, Controller…)

- Given a piping and instrumentation drawing (P&ID), correctly identify, interpret and label the instrument, location and signal type symbols

- Differentiate between discrete, multistep, and continuous controllers

- Describe the general goal of controller tuning

- Describe the basic mechanism, advantages and disadvantages of the following mode of controller action : Proportional, Integral and Derivative

- Identify the basic implementation of P, PI and PID control in the following types of loops : Pressure, Flow, Level and Temperature loops

- Differentiate feedback and feedforward control loops

- Diagram the process control loop using ISA symbology

- Explain the basic implementation process for each of the following types of control : Cascade, Split range , Batch, Ratio and Selective controls

- Understand through extensive 3D animation the techniques and methods used in process industries to measure temperature, pressure, flow and level

- Personnel needing to learn the essentials of process control and instrumentation

- Control, Process, Chemical and Design Engineers

- Operation, technical service and maintenance professionals

- Experienced personnel as a refresher course and to broaden their knowledge

- Consultants and Sales professionals

PREVIEW THIS TRAINING COURSE

Would you like to contact us ? We are here to help !

Fore more information about this training course, please fill in the contact form hereafter then click on send :